Industrial processes often generate volatile organic compounds (VOCs) that can harm air quality and human health. Fortunately, technologies like regenerative thermal oxidizers (RTOs) and flares help us address this challenge. But how do you know which one is the better fit for your application? Let’s explore the key differences between RTOs and flares.

Regenerative Thermal Oxidizer (RTO): A Clean and Efficient Option

- Function: Regenerative Thermal Oxidizers destroy VOCs in an exhaust stream by burning them at high temperatures (typically exceeding 760°C or 1400°F). This process converts VOCs into harmless byproducts like water vapor and carbon dioxide.

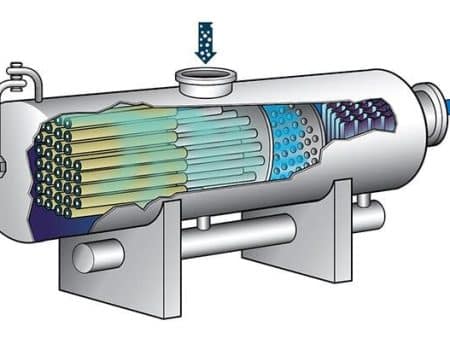

- Regenerative Thermal Oxidizer Working Principle: An RTO uses a ceramic media bed that captures heat from the hot, VOC-laden exhaust. This heat is then used to preheat the incoming polluted air before it enters the combustion chamber, significantly reducing fuel consumption. The ceramic bed alternates between heating and cooling phases to achieve optimal efficiency.

- Advantages: RTOs offer exceptional VOC destruction efficiency, making them suitable for a wide range of applications. They are also known for their durability and reliability.

- Disadvantages: The high operating temperatures of RTOs can lead to increased fuel costs, especially when dealing with low-concentration VOC streams.

Flare: A Simple Solution for Specific Scenarios

- Function: Flares are essentially open or enclosed combustion devices that safely dispose of waste gases with high VOC concentrations (typically exceeding 3-5% of the Lower Explosive Limit or LEL).

- Working Principle: The waste gas stream is continuously combusted in the flare tip, resulting in the destruction of VOCs.

- Advantages: Flares are a relatively simple and cost-effective solution for high-concentration VOC streams. They require minimal maintenance and can handle large fluctuations in flow rates.

- Disadvantages: Flares do not recover heat from the combustion process, leading to higher fuel consumption and costs compared to RTOs. They are also less efficient at destroying VOCs in low-concentration streams. Additionally, open flares can generate visible emissions and noise pollution, often causing many to opt for RTO’s over flares.

Choosing Between RTO and Flare

Several factors influence the choice between an RTO and a flare, including:

- VOC concentration: Flares are better suited for high-concentration VOC streams.

- Environmental regulations: Some regions may have stricter emission limits that favor RTOs.

- Fuel costs: RTOs can be more economical in the long run for applications with continuous operation or low-concentration VOC streams.

- Process considerations: Flares might be preferable for processes with large variations in flow rate.

Both RTOs and flares are valuable tools for industrial air pollution control. Selecting the right technology depends on your specific needs and operating conditions. Consulting with one of our air quality specialists is vital before making a final decision. We can help you determine the most effective and cost-efficient solution for your facility. Please contact us today to learn more.