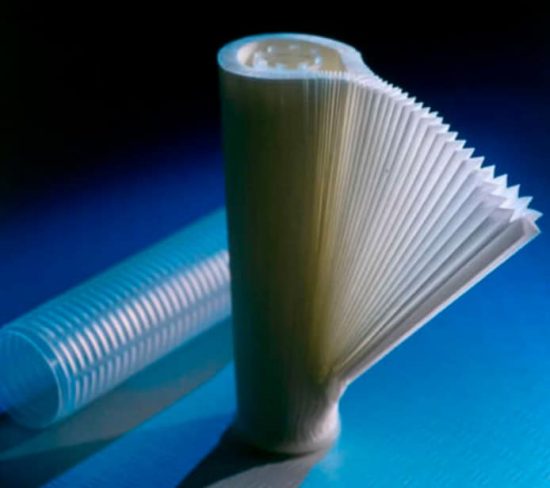

Wound Depth Filter Cartridges

Mefiag Wound Depth Filter Cartridges are fabricated of natural fibers, such as cotton, or synthetic fiber wound over a perforated plastic or metal core. The precision winding pattern covers the entire depth of the filter tube with hundreds of funnel shaped tunnels which become gradually finer from the outer surface to the center of the tube and trap progressively finer particles as the fluid travels to the center. This allows much greater solids retention capacity than is associated with surface filter media of the same dimensions.

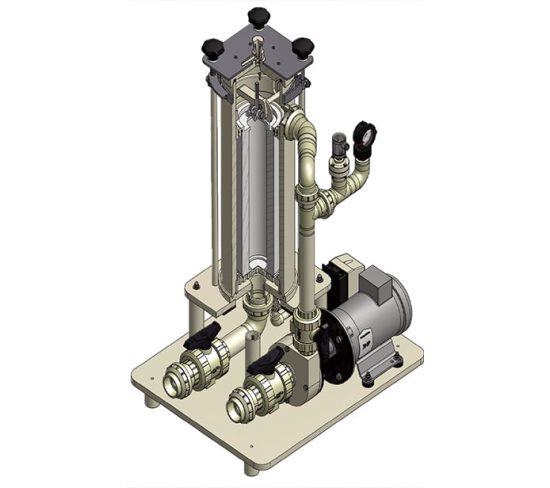

Beginning in 1953, Mefiag has since emerged as a worldwide leader in providing first-class filter solutions. Our advanced filtration and pump solutions go above and beyond in the anodizing, plating, and metal finishing industries. Our products deliver in the toughest conditions. When the work is hard, Mefiag filters work harder.

Mefiag supplies the most versatile products on the market. In addition to our filtration solutions for electroplating, our pumps and filters are also used in diversified businesses worldwide. Companies know they can count on our products to efficiently filter and dispose of harmful substances. Even as our expertise broadens, one thing never changes: our promise to craft reliable, efficient products for our clients. When you choose a Mefiag filtration solution for your business, you are choosing with confidence.

At Mefiag, we are proud of our tradition. From our first day to our last, we strive to provide hard-working products for hard-working people. If you strive for perfection as consistently as we do, then you can trust Mefiag to provide your company with the excellence and dependability it deserves. For the optimum filtration solution, choose Mefiag.

FEATURES & BENEFITS

- Standard sizes

- Designed for corrosion resistant service

- Low Total Cost of Ownership

- High flow rate – low pressure drop

- Long service life – high solids holding capacity

- Easy maintenance

APPLICATIONS

- Automotive

- Construction

- Sanitary

- Plating

- Anodizing

- Metal Finishing

- Labs

- Small Plating Tanks