Vent and Blowdown Silencer

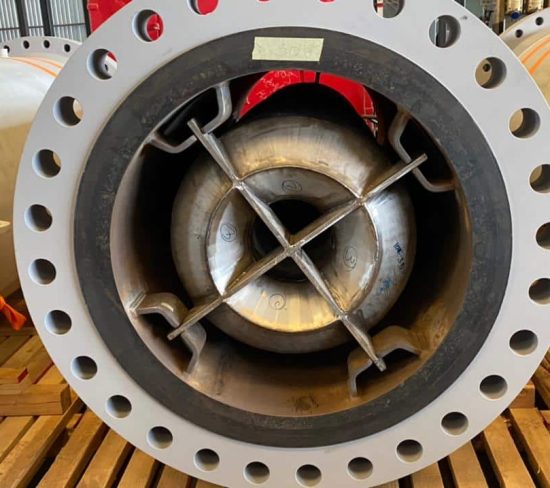

A Vent and Blowdown silencer is used to control the noise associated with venting pressurized gases to atmosphere. Our Burgess-Aarding brand Vent and Blowdown Silencer is offered in a wide range of standard and custom designs used in applications for natural gas, steam, air, or virtually every other pressurized gas.

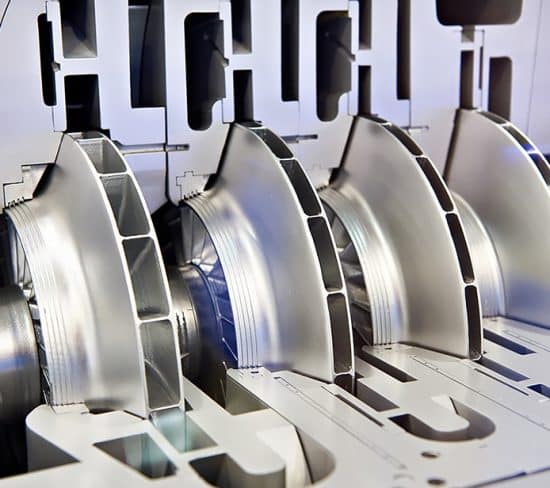

Our vent and blowdown silencer solutions are available with optional designs to increase efficiency and performance, including single or multiple inlets, multi-stage diffusers, and acoustically lined shells or absorptive panels packed with mineral wool or fiberglass packing. Plus, our designs feature “Advanced Micro-Diffusion,” which can dramatically reduce the silencer size and weight.

For our standard Vent and blowdown silencers we have the SST silencers. With our extensive experience in designing customized Vent Silencers we have utilized this knowledge to come up with a revolutionary small silencers. With these high performing silencers we can support you with a quick delivery against a very competitive price.

FEATURES & BENEFITS

- Design features include single or multiple inlets, multi-stage diffusers, acoustically lined shells, or absorption panels packed with mineral wool or fiberglass packing

- Advanced Micro-Diffusion design

- Model designs up to 60 dB

- Custom accessories include supports, weather hoods, bird screens, and directional outlets

- Low Total Cost of Ownership

- Maximum efficiency and performance, providing noise reduction up to 60 dB

- High value with premium quality construction materials – carbon, stainless steel, and higher alloy makeup materials provide longer service with high temperatures and corrosive environments

- High reliability due to ASME (American Society of Mechanical Engineers) design practices