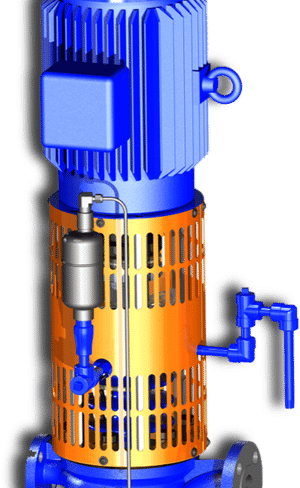

Series 3000 Recessed Impeller Horizontal Pump

As the leader in corrosion-resistant fiberglass pumping equipment, our Fybroc brand confidently delivers solutions designed to handle corrosive liquids and optimize efficiency and performance. These solutions are tailored to your difficult corrosive or abrasive pump challenges.

The Fybroc Series 3000 is a custom-designed Recessed Impeller Horizontal Pump featuring a recessed impeller design, manufactured with Fiberglass Reinforced Polymers (FRP) for corrosion resistant durability, structural integrity, and dependable service. Our pumps provide smooth flow-through pumping for heavy duty applications and are available in five sizes.

FEATURES & BENEFITS

- Capacities to 2400 GPM (272 m3/hr)

- Fiberglass reinforced plastic (FRP) construction

- Heads to 130 feet (40 m)

- Working temperatures to 212°F (100°C)

- Working pressures to 175 PSI (1,207 kPa)

- VR-1, VR-1A, BPO-DMA, EY-2 materials

- High strength casings with integral 150 lb. FF flanges

- Tangential discharge connection

- Back pull-out design

- Power frame interchangeable with 1500/1600 series

- FRP baseplates available

- Low Total Cost of Ownership

- High durability – designed for heavy duty pumping applications

- Internal clearances permit pumping of corrosive solids with minimal impeller contact

- Optimal performance with less than 10% impeller contact with liquid

APPLICATIONS

- Chemical Processing

- Electric Utilities

- Pulp and Paper

- Electronics

- Scrubbers

- Aquariums/Aquaculture

- Desalination/Water Reuse

- Reverse Osmosis

- Commercial Marine/Navy