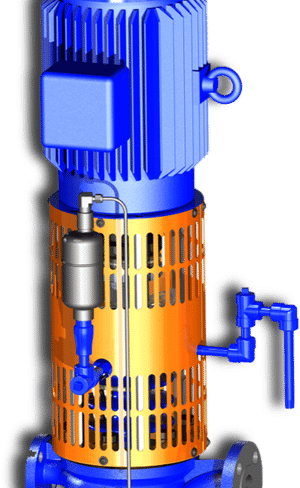

RAV SERIES AIR COOLED VERTICAL INLINE THERMAL LIQUID PUMP

Each of our Dean RAV Series Air Cooled Vertical Inline Thermal Liquid Pumps is custom engineered to deliver optimal performance, efficiency, and reliability, and is an ideal choice for heat transfer and hot oil applications. The RAV Series pump features a shaft mounted fan to provide air flow over the cooling fins of the pump. This air-cooled design eliminates the need for external water cooling for the bearings and mechanical seal.

Our RAV Series vertical inline pumps are designed to minimize alignment concerns and save space and are available in six sizes with corrosion resistant construction, representing the highest quality and most cost-effective thermal liquid pumping equipment available today.

Dean products are known worldwide for their exceptional reliability and durability. We craft state-of-the-art chemical process and high temperature metallic centrifugal pumps. Dean pumps are manufactured with precision, enabling them to withstand corrosive chemicals and extreme temperatures. The Dean RAV Series Air Cooled Vertical Inline Thermal Liquid Pumps are representative of this legacy.

Dean pumps excel at harnessing kinetic energy to move hazardous liquids safely and efficiently through every stage of the transportation process. Our pumps are designed to deal with the severe rotational stress, heat, pH, and the other issues of transporting dangerous liquids.

Dean features a wide variety of primary products and pump solutions to fit all your facility needs. Choose from one of our ANSI chemical process pumps, vertical inline pumps, air-cooled high temperature pumps, and heavy-duty high-temperature pumps to address your particularly extreme application requirements. Dean has the ideal pump for you, and it comes with the finest customer service in the business. See for yourself why Dean pumps are used by some of the largest companies around the world.

FEATURES & BENEFITS

- Custom designs in six sizes to meet your specific application needs

- Premium quality corrosion resistant construction materials

- Capacities to 360 GPM (82 m3/hr)

- Heads to 320 feet (98 m)

- Pumping temperatures to 650°F (343°C)

- Working pressures to 350 PSIG (2,413 kPa)

- Space saving design

- 300 lb. RF flanges

- Standard C-face motors

- Compatible to NEMA/IAC motor frame sizes

- Minimizes alignment concerns

- Low Total Cost of Ownership

- High value and long life

- Low maintenance and easy installation process

APPLICATIONS

- Hot Oil

- Heat Transfer

- OEM (Original equipment manufacturers) Applications

- Commercial

- Hospitals

- Universities

- Laundries

- Prisons